P050B Cold start ignition timing performance

June 28, 2017

Add Comment

P050B code, cold start condition, ambient Air temperature between -7°C and 50°C (19.4°F and 122°F), engine Coolant temperature between -7°C and 50°C (19.4°F and 122°F), the difference between the Ambient Air temperature and ECT temperature at start is equal to or less than 10°C (50°F), engine running at idle only.

Possible causes P050B code:

Set conditions P050B code, engine speed is 50 rpm or more (depending on vehicle specification) below desired idle speed for at least 3 seconds and the average spark advance is above the threshold, too much spark advance, for a specified time limit. Default actions the MIL light illuminate.

Possible causes P050B code:

- Restricted intake air system

- Low battery voltage

- Fuel contamination

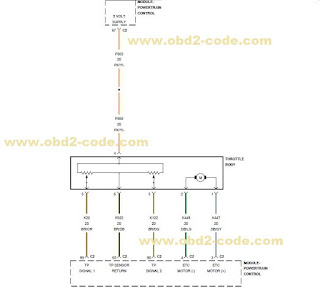

- Excessive resistance in the ETC positive circuit

- Excessive resistance in the ETC negative circuit

- ETC Motor/Throttle Body

- Powertrain Control Module (PCM)

Diagnose P050B Cold start ignition timing performance

Step 1. Check for an active DTC

Turn the ignition on. Low battery voltage can also cause excessive current draw, in very hot and very cold ambient temperatures. Make sure the battery can pass a load test before continuing. Start the engine, allow the engine to reach normal operating temperature. With the scan tool, read DTC.

It may be necessary to drive the vehicle to meet the conditions to set this DTC, try to repeat the conditions in which the fault originally set by reviewing the Freeze Frame data.

Is the DTC active or pending ?

Yes, go to step 2.

No, perform the PCM intermittent condition.

Step 2. Throttle plate inspection

Turn the ignition off, remove the air cleaner assembly from the throttle body. Check for any signs of a foreign material (ice, dirty, or excessive carbon build up) on the throttle plate or in the bore causing the throttle plate to stick.

Were any signs of foreign material or scoring of the throttle plate or bore found ?

Yes, remove the debris if possible or replace the throttle body assembly. Disconnect the battery when replacing the Throttle Body Assembly. After installation is complete, use scan tool and select the ETC RELEARN function on the misc function tab scanner.

No, go to step 3.

Step 3. Dirty air filter

Remove and inspect the air filter.

Is the Air Filter dirty ?

Yes, replace the Air Filter.

No ,go to step 4.

Step 4. Contaminated Fuel

Inspect the Fuel for contamination (Dirty, water, or other foreign material).

Is the fuel contaminated ?

Yes, drain the Fuel from the fuel tank into an approved gas holding tank and add clean fuel.

No, go to step 5.

Step 5. Excessive resistance in the ETC positive circuit

Turn the ignition off, disconnect the PCM harness connector.

Caution : Do not probe the PCM harness connectors. Probing the PCM harness connectors will damage the PCM terminals resulting in poor terminal to pin connection.

Using voltmeter perform a voltage drop test. Back probe the ETC Positive circuit at the Throttle Body harness connector and PCM harness connector. Make sure the voltmeter leads are connected so a positive polarity is displayed on the voltmeter.

Start the engine and allow it to reach normal operating temperature. Monitor the voltmeter.

Is the voltage below 0.5 volt ?

Yes, go to step 6.

No, repair the exessive resistance in the ETC positive circuit.

Step 6. Excessive resistance in the ETC Negative circuit

Turn the ignition off, move the voltmeter leads to back probe the ETC Negative circuit at the Throttle Body harness connector and PCM harness connector. Make sure the voltmeter leads are connected so a positive polarity is displayed on the voltmeter. Start the engine and allow it to reach normal operating temperature. Monitor the Voltmeter.

Is the voltage below 0.5 volt ?

Yes, go to step 7.

No, repair the excessive resistance in the ETC Negative circuit.

Step 7. ETC Motor

Turn the ignition off, connect the Throttle Body harness connector. Measure the resistance of the ETC Motor by probing the PCM harness connector for the ETC Positive circuit and the ETC Negative circuit.

Is the resistance between 2.5 and 25 ohms at closed throttle ?

Yes, go to step 8.

No, verify that there is good pin to terminal contact in the throttle body and Powertrain Control Module (PCM) Connectors. Replace the Throttle Body assembly if no problems were found in the connectors. Disconnect the battery when replacing the Throttle Body assembly. After installation is complete, use a scan tool and select the ETC RELEARN function on the Misc function tab scanner.

Step 8. Check related PCM and component connections

It may be necessary to drive the vehicle to meet the conditions to set this DTC, try to repeat the conditions in which the fault originally set by reviewing the Freeze Frame data.

Is the DTC active or pending ?

Yes, go to step 2.

No, perform the PCM intermittent condition.

Step 2. Throttle plate inspection

Turn the ignition off, remove the air cleaner assembly from the throttle body. Check for any signs of a foreign material (ice, dirty, or excessive carbon build up) on the throttle plate or in the bore causing the throttle plate to stick.

Were any signs of foreign material or scoring of the throttle plate or bore found ?

Yes, remove the debris if possible or replace the throttle body assembly. Disconnect the battery when replacing the Throttle Body Assembly. After installation is complete, use scan tool and select the ETC RELEARN function on the misc function tab scanner.

No, go to step 3.

Step 3. Dirty air filter

Remove and inspect the air filter.

Is the Air Filter dirty ?

Yes, replace the Air Filter.

No ,go to step 4.

Step 4. Contaminated Fuel

Inspect the Fuel for contamination (Dirty, water, or other foreign material).

Is the fuel contaminated ?

Yes, drain the Fuel from the fuel tank into an approved gas holding tank and add clean fuel.

No, go to step 5.

Step 5. Excessive resistance in the ETC positive circuit

Turn the ignition off, disconnect the PCM harness connector.

Caution : Do not probe the PCM harness connectors. Probing the PCM harness connectors will damage the PCM terminals resulting in poor terminal to pin connection.

Using voltmeter perform a voltage drop test. Back probe the ETC Positive circuit at the Throttle Body harness connector and PCM harness connector. Make sure the voltmeter leads are connected so a positive polarity is displayed on the voltmeter.

Start the engine and allow it to reach normal operating temperature. Monitor the voltmeter.

Is the voltage below 0.5 volt ?

Yes, go to step 6.

No, repair the exessive resistance in the ETC positive circuit.

Step 6. Excessive resistance in the ETC Negative circuit

Turn the ignition off, move the voltmeter leads to back probe the ETC Negative circuit at the Throttle Body harness connector and PCM harness connector. Make sure the voltmeter leads are connected so a positive polarity is displayed on the voltmeter. Start the engine and allow it to reach normal operating temperature. Monitor the Voltmeter.

Is the voltage below 0.5 volt ?

Yes, go to step 7.

No, repair the excessive resistance in the ETC Negative circuit.

Step 7. ETC Motor

Turn the ignition off, connect the Throttle Body harness connector. Measure the resistance of the ETC Motor by probing the PCM harness connector for the ETC Positive circuit and the ETC Negative circuit.

Is the resistance between 2.5 and 25 ohms at closed throttle ?

Yes, go to step 8.

No, verify that there is good pin to terminal contact in the throttle body and Powertrain Control Module (PCM) Connectors. Replace the Throttle Body assembly if no problems were found in the connectors. Disconnect the battery when replacing the Throttle Body assembly. After installation is complete, use a scan tool and select the ETC RELEARN function on the Misc function tab scanner.

Step 8. Check related PCM and component connections

0 Response to "P050B Cold start ignition timing performance "

Post a Comment